3D Modeling

For all types models and prototypes to be made ONE OFF requires the client to provide the 3D file in order to reduce time, costs and eliminate potential misunderstandings. All file formats of the most common 2D and 3D CAD software are acceptable. There are a few simple rules to be considered during the 3D modeling phase that reduce corrective measures during the pre-production phase.

Acceptable file formats: *.igs, *.stl, *.dxf, *.dwg, *.3dm, *.stp,* .3ds, *.lwo, *.raw, *.mgx, *.skp

Should the 3D file not be available, ONE OFF can provide support for constructing CAD models, correcting available files and creating 3D mathematical models from 2D files or hard copy drawings.

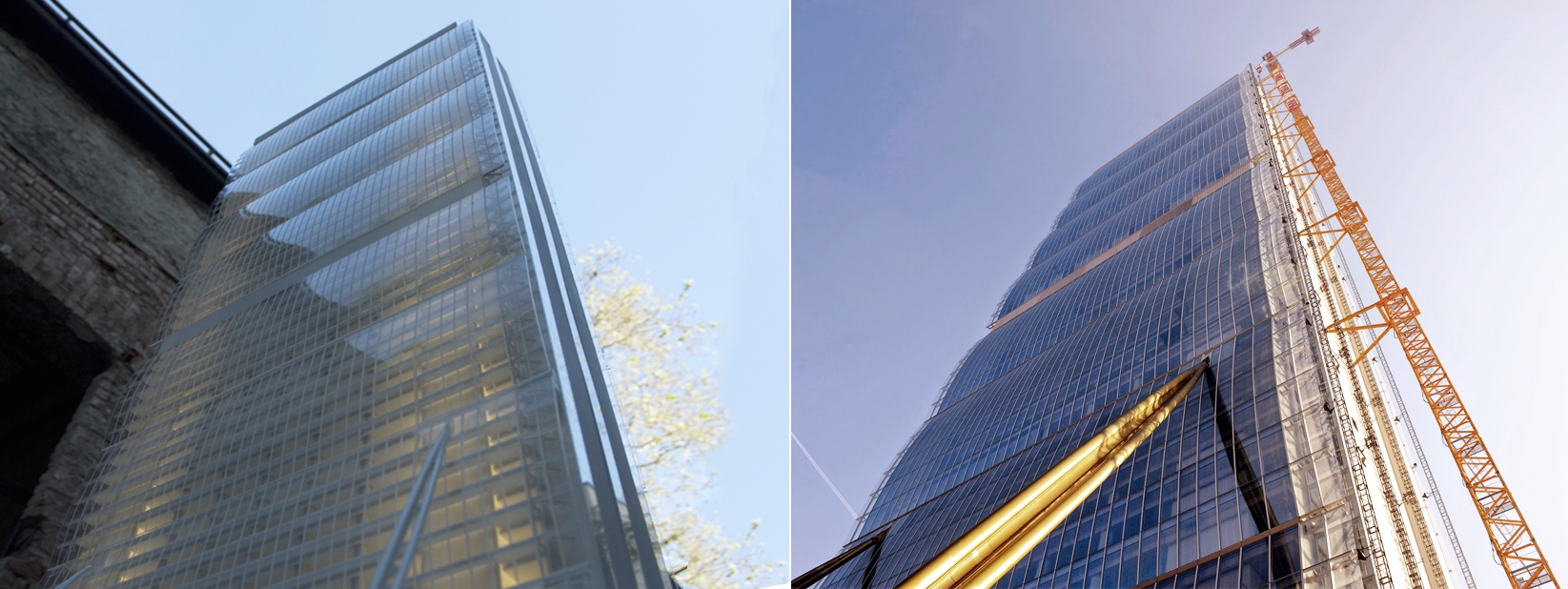

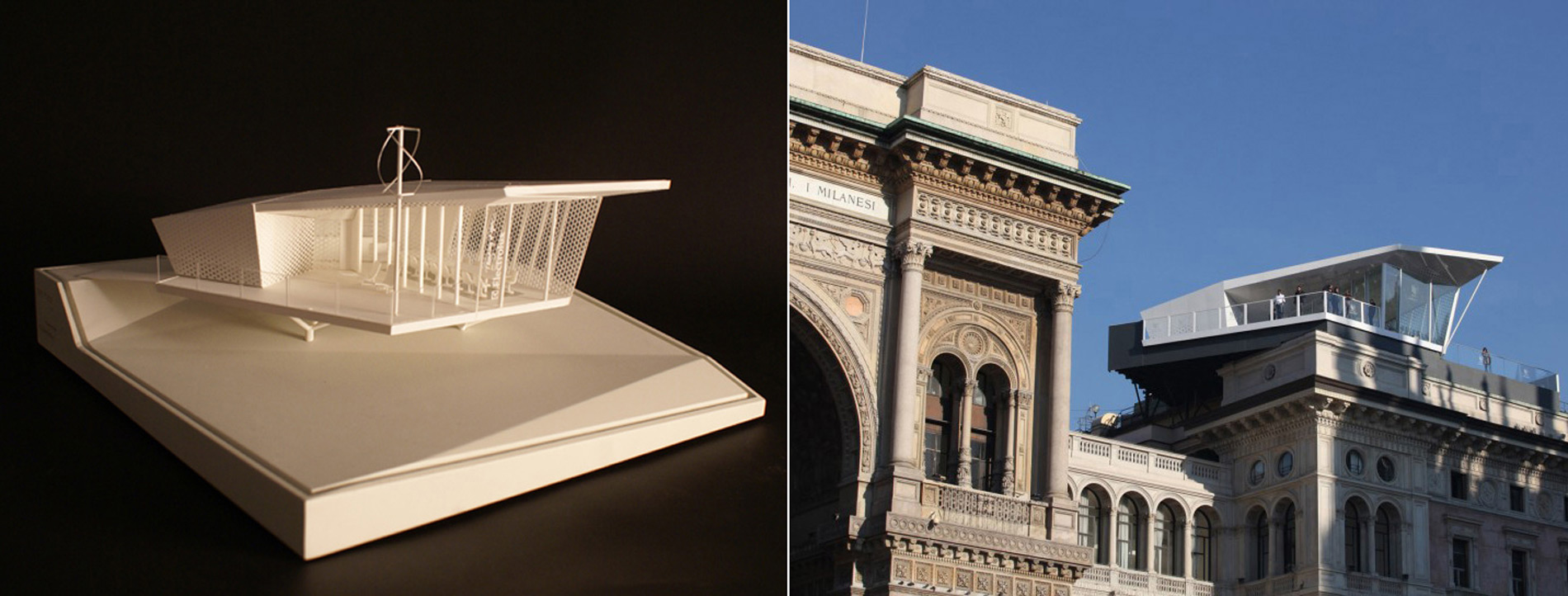

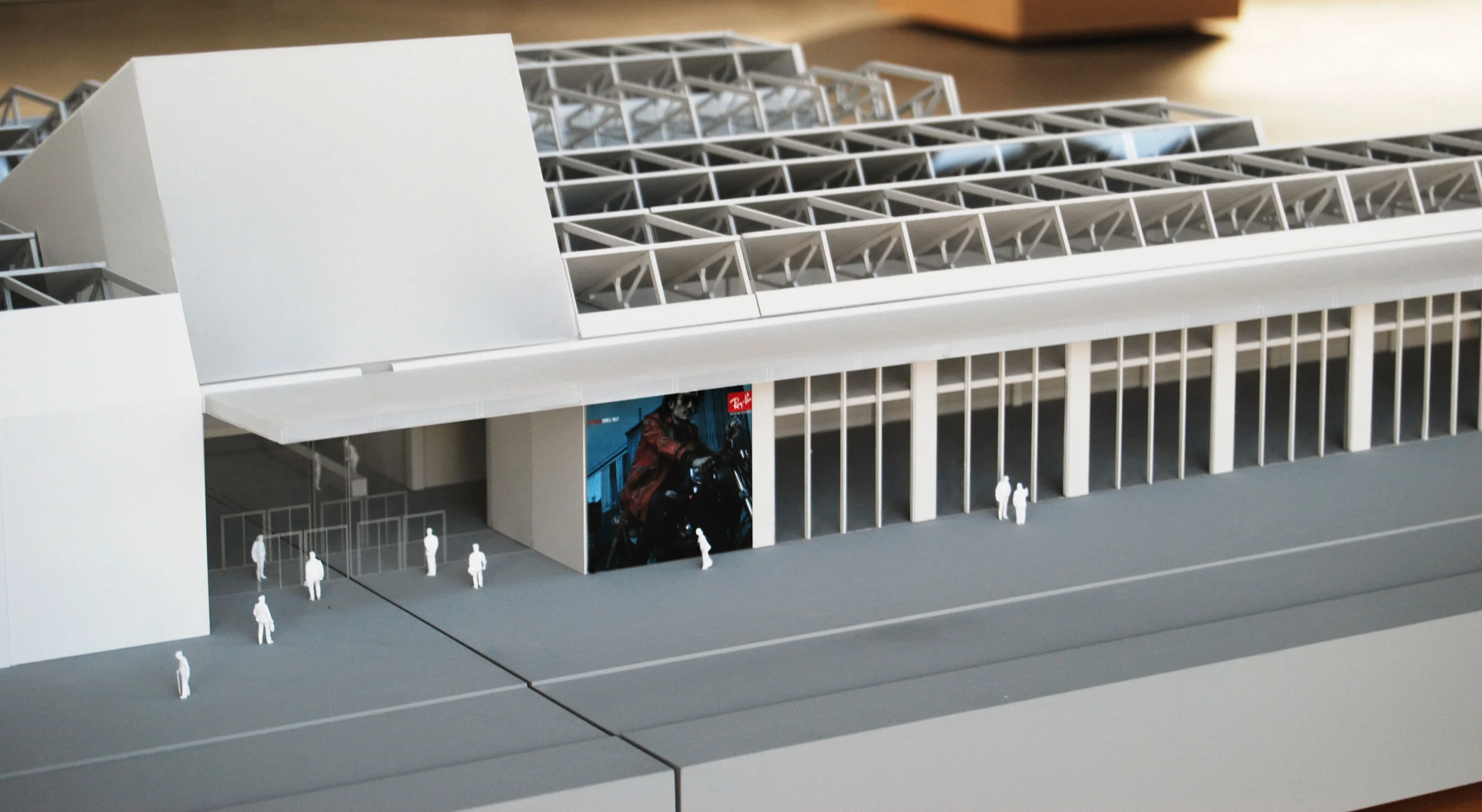

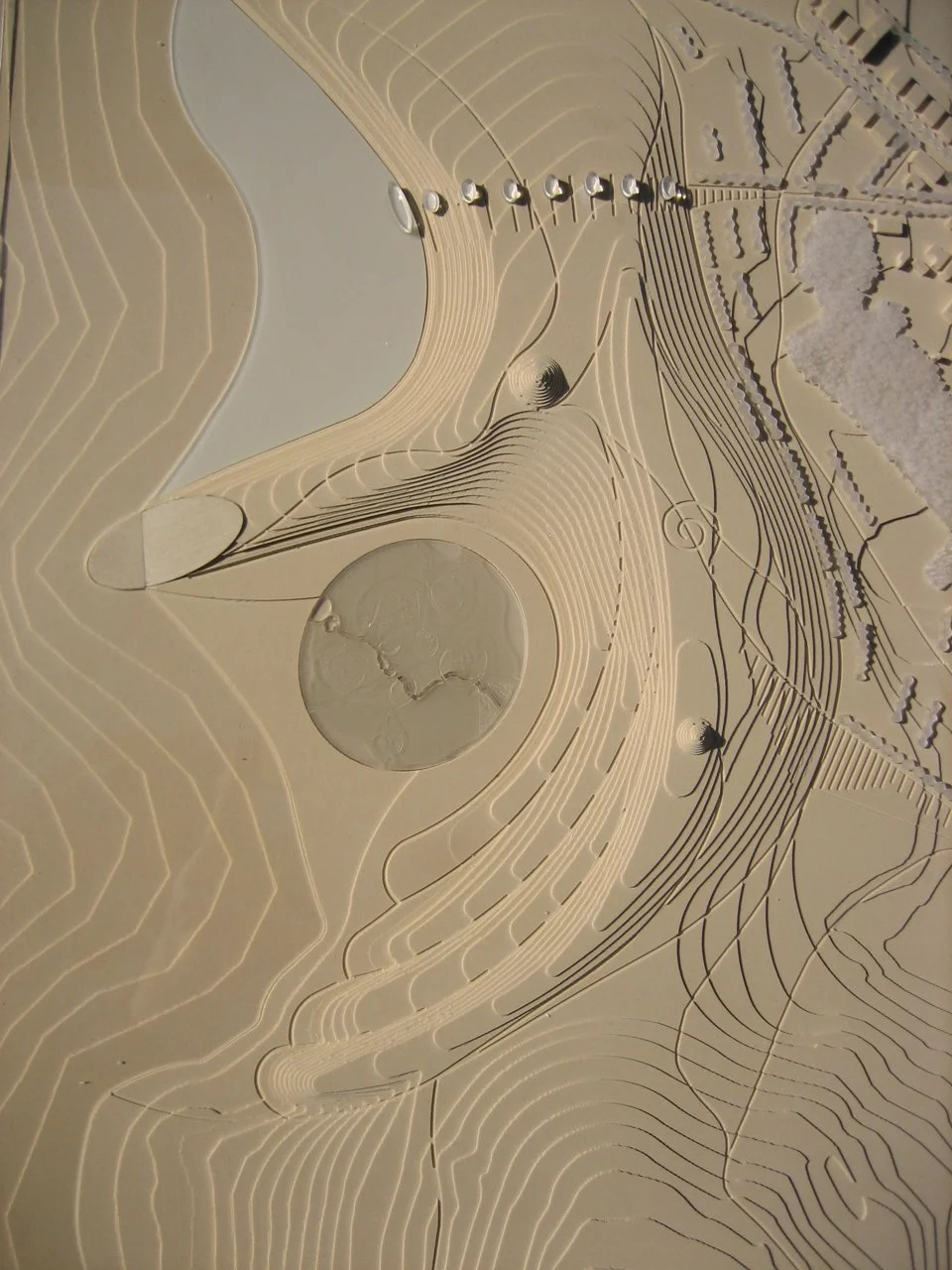

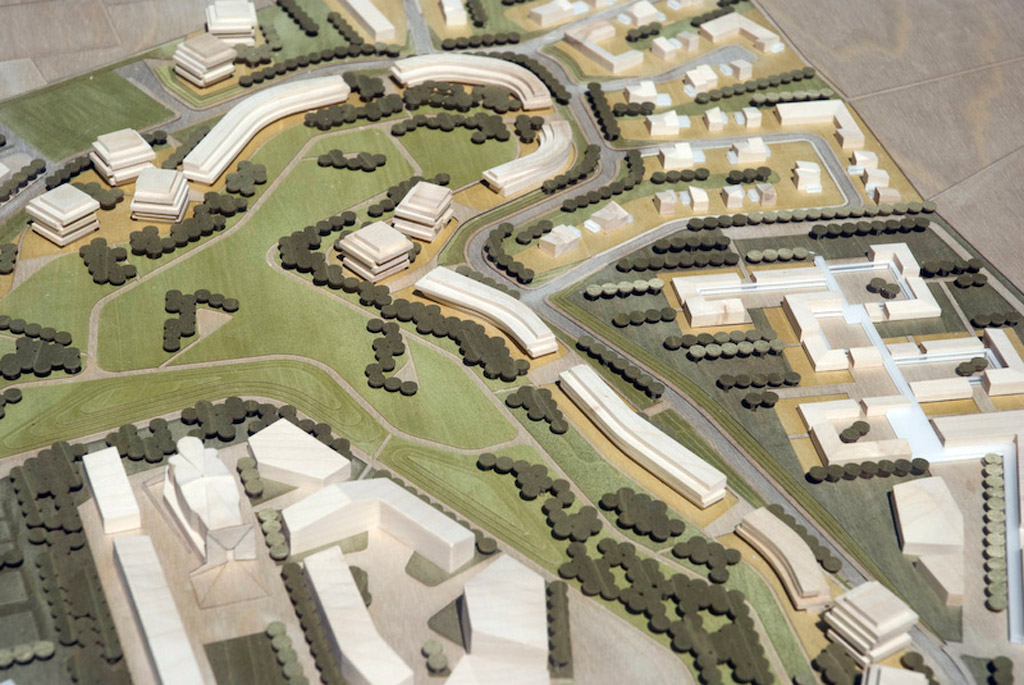

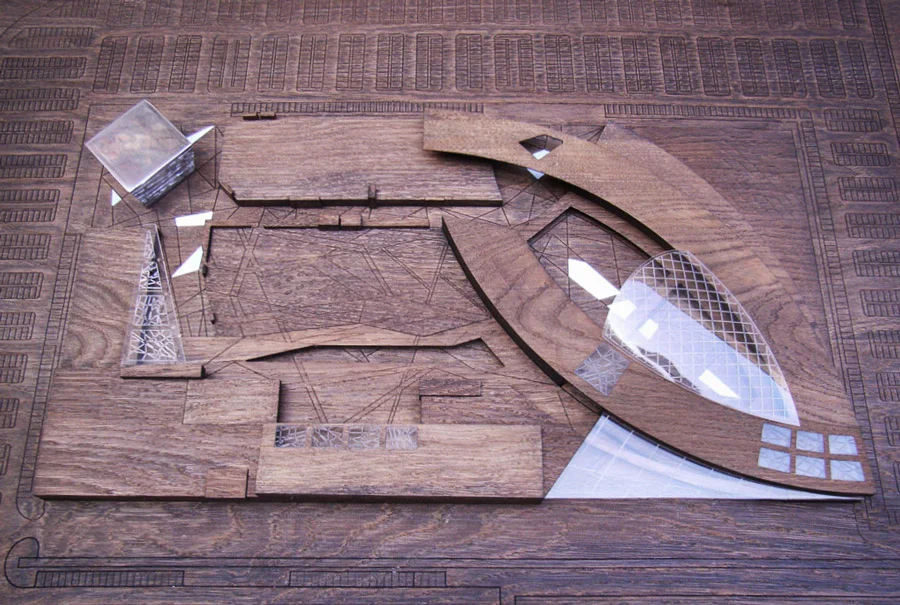

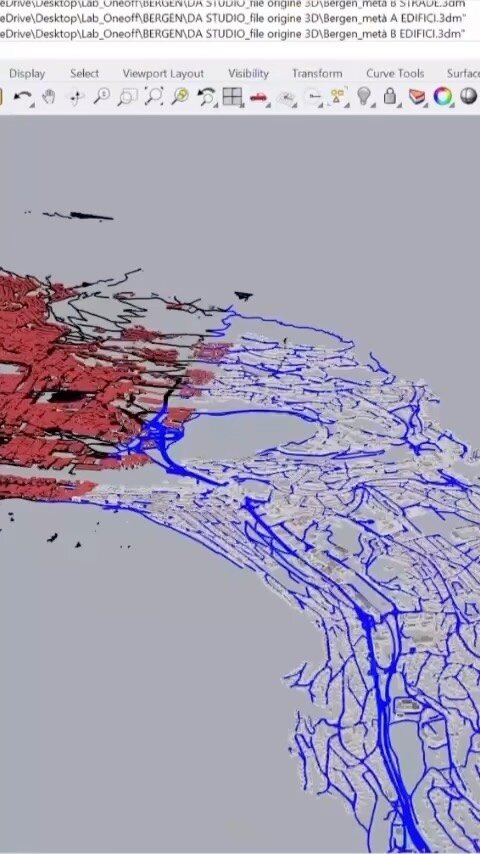

1. Architectural Models

To request a quote please submit:

The purpose of model: e.g. presentation, sales office, marketing, exhibition etc.

Visual references of similar models (see our models on flickr).

The scale.

Ground Floor Plan of the project indicating only the overall area or outside dimension.|

Presentation rendering of the project.

3D Model.

3D file requirements for creating an architectural model:

The 3D model should be a true representation of what is effectively expected, with a level of detail that is adequate to the scale of representation.

The file should be created in layers, according to materials, groups, elements, areas etc.

Details and finishes to be etched (e.g. flooring, window frames etc.) should be provided in a 2D file.

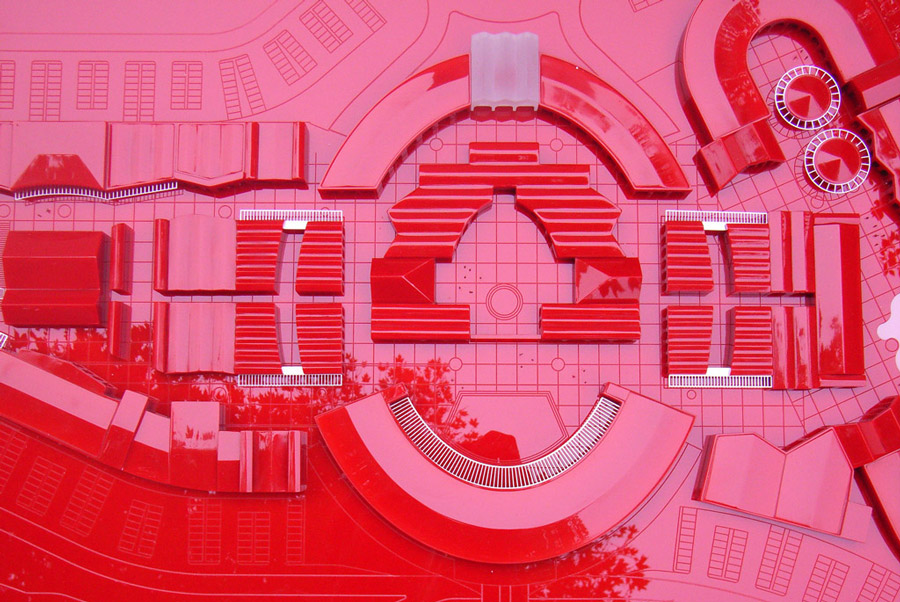

2. Mockups

To request a quote please submit:

The purpose of the mockup: e.g. presentation, photo-shoot, etc.

The scale.

Presentation rendering of the project.

3D Model.

3D file requirements for creating a mockup:

True representation of the model.

The file should be created in layers, according to materials, colours etc.

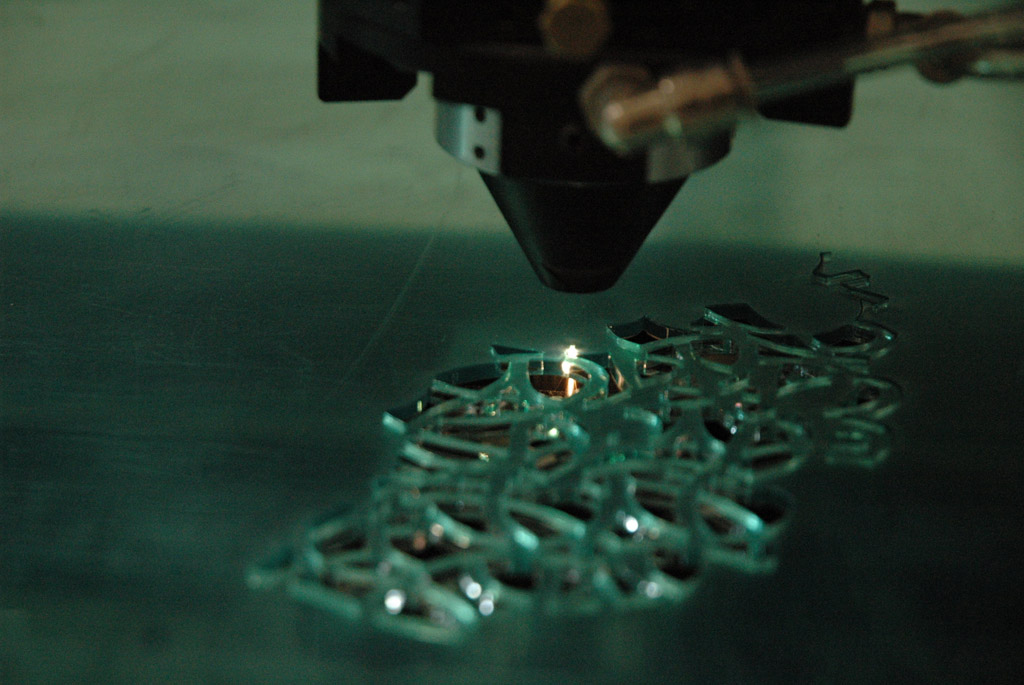

3. Laser Cutting

To request a quote:

To use our laser cutting service please provide a file with a drawing of the pieces to be cut and etched, set in an area with overall dimensions not exceeding 1590 x 1990 mm and a maximum material thickness of 20 mm.

The materials to be used (Card, Cardboard, Fabric, Leather, Plywood, Wood, Plexiglas, Methacrylate, Petg, Styrene etc.) are normally supplied by the client.

Materials:

Materials for cutting: plastics, acrylics, wood, fabric, leather, paper, cardboard

Materials for engraving: plastics, acrylics, wood, fabric, leather, paper, stone.

Organic materials: acrylic resins, polyethylene, polypropylene, polycarbonate, natural and synthetic rubber, PVC, wool, cotton, leather, wood.

Inorganic material: glass, ceramic, quartz, alumina, mica, natural rock

2D file requirements for laser cutting:

The file should include separate layers for for laser cutting and engraving, specifying the type of material and thickness.

The parts to be cut should be drawn with a minimum distance of 2 mm between each one.

Avoid duplicate lines or superimposed lines.

Create separate files according to type and thickness of material: each file should contain pieces to be cut and engraved in the same material and the same thickness.

Acceptable file formats: *.3dm, *.dwg, *.dxf, *.ai, *.pdf.

Once files have been checked a quote will be provided. Following client acceptance of the quote, ONEOFF guarantees delivery within 24/48 hours.

4. Rapid Prototyping

To request a quote please submit:

The purpose of the prototype: e.g. to check dimensions, ergonomics, mechanics, presentation etc.

Modeling technique and materials required, if known.

The 3D file of a 1:1 scale of the prototype in millimetres.

3D file requirements for creating a prototype:

Create a true representation of the model, avoiding discontinuous or overlapping surfaces (use the appropriate snap fixings during assembly phase).

Create the 3D file of the object ensuring it is manifold: it cannot include surfaces that do not have a thickness.

Ensure that thicknesses of >=1mm are given to gaps, joints and shadowlines so that they are clearly marked and consistent.

Wherever possible avoid thicknesses of less than 1.5 mm: where this is not possible please flag these before requesting a quote.

Organise model construction in layers so that unnecessary references (centrelines, construction lines, profile references etc.) can be eliminated during production.

Provide a 2D dimensioned drawing as size reference.

5. CNC Milling

To request a quote:

To use our CNC milling services please submit 3D file of a 1:1 scale of the model in millimetres. Maximum work area is 990x1490mm, and maximum height is 300 mm.

Specify the purpose of the piece: e.g. verification of dimensions, ergonomics, mechanics etc.

Indicate the required material, if known.

3D file requirements for CNC milling:

Create a true representation of the model, avoiding discontinuous or overlapping surfaces (use the appropriate snap fixings during assembly phase).

Create the 3D file of the object ensuring it is manifold: it cannot include surfaces that do not have a thickness.

Ensure that thicknesses of >=1mm are given to gaps, joints and shadowlines so that they are clearly marked and consistent.

Wherever possible avoid thicknesses of less than 1.5 mm: where this is not possible please flag these before requesting a quote.

Organise model construction in layers so that unnecessary references (centrelines, construction lines, profile references etc.) can be eliminated during production.

Provide a 2D dimensioned drawing as size reference.

info@oneoff.it

Appointments and or/collection of models or orders

can be made during the following opening hours:

Monday-Friday: 9:00 / 13:00 – 14:00 / 18:00